The rise of satellite constellation manufacturing activity has had a direct impact on the space industry value chain.

Manufacturers are increasingly interested in the potential of incorporating automotive industry-inspired assembly lines to meet their satellite production demands at scale.

The fundamental premise of this development is that anything built on an assembly line can take advantage of the standardisation of all interfaces (electrical, mechanical, etc.) and a streamlined supply chain.

When applied to high volumes of systems in production, this enables manufacturers to reap the substantial benefits of reduced per unit costs and shorter delivery timelines.

The space industry is currently witnessing the emergence of several different approaches to mass manufacturing of satellites which are interesting to review for the long-term sustainability of the NewSpace revolution.

Satsearch has been tracking these developments in the space industry supply chain and we see three distinct models of satellite constellation manufacturing coming to the fore.

Model 1 – Internalised, fully vertically-integrated manufacturing plus services

This approach is an integration of the upstream and the downstream capabilities within the core competency of a company in order to deliver a service on the basis of a fully vertically-integrated capability.

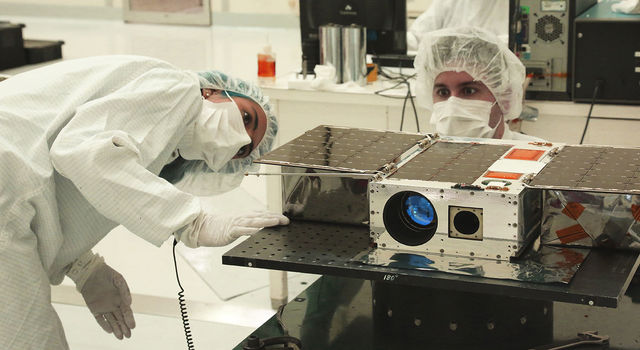

The typical example of this is a company such as Planet which is producing its own satellites, has its own ground and data cloud assets, to receive and deploy the service, and is now moving into standardising end-user services in established downstream markets (e.g. agriculture, infrastructure, etc.)

The full-stack vertical integration at Planet gives them the ability to enhance their agility so they can rapidly and iteratively develop new features and capabilities for satellites based on updated technologies as well as changing user requirements.

To date, the space industry has seen this model emerge mostly within the Earth Observation (EO) domain. This is arguably because the number of moving parts in such a fully vertically-integrated manufacturing plus services model is much smaller in the EO domain compared to the communications domain.

However, there are companies now seeking to challenge this approach. The main examples of the fully vertically-integrated solution in action that the industry could see in the coming years are likely to be in developments by SpaceX and Blue Origin, who not only are investing into building the satellites but also in launching them, with their own rockets, to orbit.

Model 2 – Competence-based co-investment and partnership-based vertical integration for manufacturing plus services

This model involves the integration of the competencies of an established incumbent trying to evolve their business with the offers of new entrants looking to disrupt the industry by providing services that use innovative new architectures.

The typical example of this model is Airbus which has co-invested and partnered with OneWeb to set up a dedicated manufacturing facility and an assembly line in order to develop the satellites for the OneWeb constellation.

One could argue that OneWeb is looking to leverage both the upstream and downstream innovation in the value chain and is trying to orchestrate service innovation reliant on competence-based co-investment and partnerships.

Simply put, this model is a strategy to line up external competences in order to vertically integrate the supply chain while taking advantage of the expertise and experience of the incumbents in the hope of achieving a high-reliability solution.

Another prominent example is LeoStella; a joint effort between Thales Alenia Space and Spaceflight Industries which is producing the satellites for the BlackSky Global constellation.

We should note that at present it is debatable whether this method can achieve the lowest cost per unit because of the nature of the size and scale of the operations of the incumbents who are involved.

Model 3 – White labelled manufacturing services

The models described earlier involve a full-stack approach that includes coordinating design, development, manufacturing, operations and providing an end-service to the market.

However, not all business models may need to line up in a strategy where the full vertical integration is achieved by creating competence directly within the company or by having co-investors act as partners within the company.

It could instead be achieved by paying a reliable and low-cost manufacturing partner who can also provide the assets and resources needed in order to offer a relevant service.

The manufacturing partners in this model not only bring deep expertise and cost benefits, but also add a layer of agile capabilities needed by the service provider to undertake some phased scaling-up of establishing the constellation.

An example of this approach in the industry is a company such as GomSpace which is supporting several constellations for operators like Sky and Space Global, helping them test an initial on-orbit system based on which the operator can then scale according to product-market fit.

This kind of ‘white labelling’ of the manufacturing service allows companies to cater to multiple service providers at the same time.

However, such white labelling does not provide an opportunity for the companies pursuing such a strategy to take a piece of the services pie, which is mostly where the business value today is created.

A similar, and very interesting, strategy of combining off-shoring manufacturing in low-cost destinations with such white labelling is being pursued by Berlin Space Technologies.

The company has entered a joint venture with an Indian business Azista to establish a low-cost, mass-manufacturing facility in India that will allow them to leverage both the value of their Intellectual Property (IP) and the operational advantages of off-shoring in order to pass on value and cost-savings to customers.

Conclusion

It will be interesting to watch in the near future as these different production scenarios play out.

Each model offers alternate tactical business advantages to stakeholders in the industry as they try to compete against each other to provide the best value to end-users.

Manufacturing quality, speed and cost could become some of the key differentiating factors for space technology companies in the near future.

As we continue to build the global marketplace for space here at satsearch and work to open up the international supply chain, understanding and discussing the processes that suppliers at all levels need to play a role in will help more smaller firms be prepared.

Thank you for reading – if you think we’ve left out any other manufacturing production models in this overview please contact us (just email [email protected]) and let us know. In addition, if you have expertise in this area (or in other aspects of the space industry) that you would like to share with the satsearch community, we’d love to hear from you!